How to Calculate electric motorcycle Parameters: Speed, Range, and Key Components

Electric motorcycle speed, range, and performance are determined by interrelated parameters such as battery voltage, capacity, motor power, and tire size. Below is a step-by-step guide to calculating these using physical formulas and engineering principles, helping users tailor configurations to their needs.

I. Core Parameter Definitions and Unit Conversion

| Parameter | Symbol | Unit | Description |

|---|---|---|---|

| Battery Voltage | V | V (Volts) | Total voltage of the battery pack (e.g., 60V, 72V) |

| Battery Capacity | Q | Ah (Ampere-hours) | Energy storage capacity (e.g., 20Ah, 30Ah) |

| Motor Power | P | W (Watts) | Rated or peak power output |

| Tire Diameter | D | mm/inches | Outer diameter of the tire (e.g., 16 inches ≈ 406.4mm) |

| Motor Speed | n | rpm (Revolutions per Minute) | Rated rotational speed of the motor |

| Motor Efficiency | η | % | Electrical-to-mechanical conversion efficiency (80%-90% typical) |

| Load Mass | m | kg | Total mass including rider and cargo |

II. Maximum Speed Calculation: Driven by Motor Speed and Tire Size

1. Tire Circumference Calculation

2. Theoretical Maximum Speed (Direct Drive, No Transmission)

vmax=1000n×C×60(km/h, converts rotational speed to hourly distance)

Example: If n=3000rpm and C=1.277m:vmax=10003000×1.277×60≈230km/h(actual speed is limited by motor power and resistance)

3. Practical Maximum Speed (Considering Power Limitations)

Account for air resistance and rolling resistance:P=21ρv3ACd+Frv(ρ = air density, A = frontal area, Cd = drag coefficient, Fr = rolling resistance)

Simplified empirical formula for power-speed relationship:vmax_real≈3resistance coefficientP×η(calibrate with industry data or tests)

III. Range Calculation: Dependent on Battery Energy, Motor Efficiency, and Load

1. Total Battery Energy

E=V×Q(Wh, e.g., 60V/20Ah battery = 1200Wh)

2. Actual Motor Power Consumption

Including motor efficiency η and load power Pload:Pactual=ηPload(load power determined by driving resistance)

3. Driving Resistance Calculation

F=Fr+Fw=mgf+21ρv2ACdFr: Rolling resistance (f≈0.01−0.02 for concrete roads)

4. Driving Time

t=PactualE×η=FvVQη(hours, assuming constant speed)

5. Range

S=v×t=FVQηv(km)

Simplified for flat roads (ignoring air resistance):S≈mgfVQηv(higher speed reduces range non-linearly)

IV. Parameter Matching: Balancing Performance for Needs

1. Prioritizing High Speed

- Key Parameters: Motor power P, speed n, tire diameter D

- Formula Insight: Increase n or D for higher theoretical speed, but require high power to overcome resistance (power scales with speed cubed).

2. Prioritizing Long Range

- Key Parameters: Battery capacity Q, voltage V, motor efficiency η, low-rolling-resistance tires

- Formula Insight: Larger Q/V increases energy; reduce resistance (e.g., lower speed, aerodynamic design).

3. Heavy Load Requirements

- Impact: Higher load m increases Fr, requiring more power or battery capacity.

- Adjustment: A 200kg load vs. 100kg may reduce range by 20%-30% (scale F with m).

V. Real-World Corrections

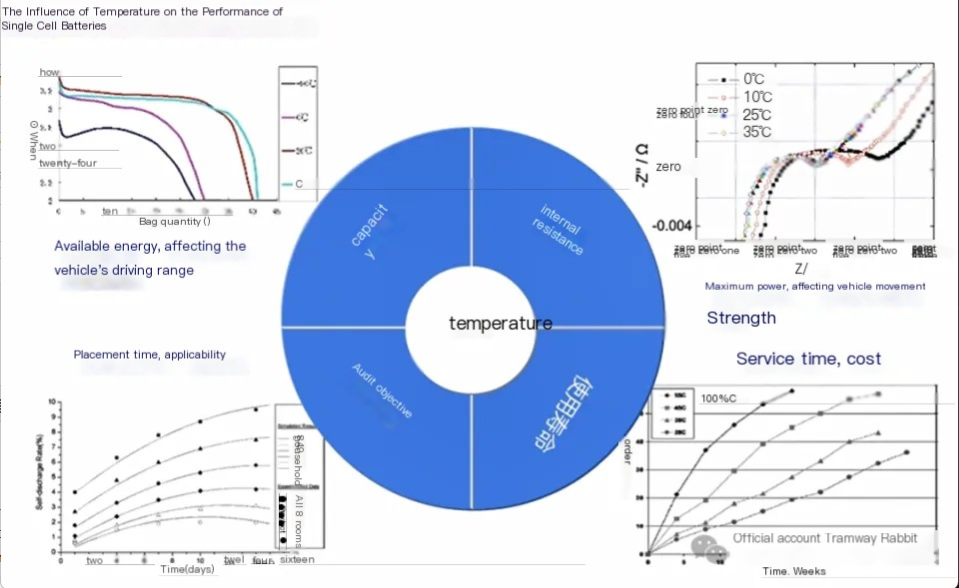

- Battery Discharge Efficiency: Capacity may drop 10%-20% in low temperatures or high-current discharge (apply a discharge coefficient).

- Road Conditions and Riding Habits: Hills and rapid acceleration increase energy consumption (range typically 50%-70% of theoretical value; use NEDC/WMTC test standards for calibration).

- Tire Factors: Wider tires increase rolling resistance (range -10%); low tire pressure (80% of standard) reduces range by 5%.

VI. Example Calculation: Basic Configuration

- Parameters: 60V/20Ah battery, 500W motor (85% efficiency), 16-inch tire (0.4064m diameter), 150kg load, constant speed 25KM/H, rolling resistance coefficient 0.015.

- Speed Calculation: At n=1500rpm, vmax≈36km/h (25km/h is practical).

- Range Calculation:

- Resistance F=150×9.8×0.015≈22.05N

- Input power Pactual=0.8522.05×(25/3.6)≈176W

- Time t=17660×20×0.85≈5.74hours

- Range S=25×5.74≈143.5km (real-world: 100-120km due to losses).

VII. Tools and Resources

Online Calculators: Use EV range simulators (e.g., EV Calculator) for automated calculations.

Industry Standards: Refer to GB/T 24158 (Chinese national standard for electric motorcycles) for testing methods.

Field Validation: Log voltage, current, and range during test rides to refine resistance and efficiency parameters.

By applying these formulas and principles, users can design parameter combinations for their specific needs (commuting distance, load, speed), balancing battery capacity, motor power, and tire size for optimal performance and cost. Always validate theoretical models with real-world data for accuracy.

Add comment

Add comment: